Determining factors in choosing the best tool for the job

Frequently we have to deal with CAD designs that are very difficult to produce a 3D model. There are pros and cons to whatever printer or mill we choose, and that choice is made considering the following factors:

- Can we yield the detail drawn in the CAD file?

In an ideal world we would print everything in resin with our DLP printer because it’s fast, can print many models at once and has the cleanest surfaces and almost perfect detail with minimal “print lines” or “grow lines.” But there are times where supports would be impossible or would degrade or damage the design. Also, resin models often present challenges in the casting process, especially with gold & silver.

- How much time will it take to produce a model?

Many times the mill is the fastest! Solidscape is definitely a slow cooker.

- Is there an easy button?

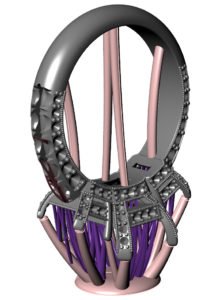

Sometimes! The easy button of model making is a Solidscape machine when it’s happy. However, there can be print lines that are a hassle to clean up in the casting and sometimes can cause degradation in the final product. There’s a lot more metal loss due to filing and grinding, and because of the way the layers are formed, there can be flaws in castings if the models aren’t sealed before the casting mold/flask is made. Solidscape models are also very fragile, and isn’t an option when your need a model quickly. The nautilus features in the model below would have been degraded by adding supports to them, and almost impossible to clean out in the casting. All “down-facing” geometry must be supported!

- What are the risks in handling the model from post print processing to casting setup?

Solidscape models are the most fragile. There’s nothing worse than printing a model for 30 hours and then having it break or crack. The mills produce fragile waxes as well, and it’s not uncommon to break a prong off when handling. The resin models almost never break, although some waxy resins have been known to have a prong break from time to time from dropping them on the floor. The model below would be ridiculously fragile and would take about 35-40 hours to print!

- What model type will produce the best casting with as much detail and precision possible? These two bands were milled in wax, and when a mill can be used it’s the best option with regards to castability and smooth surfaces.

- How technical and time consuming is the setup? Is it worth it?

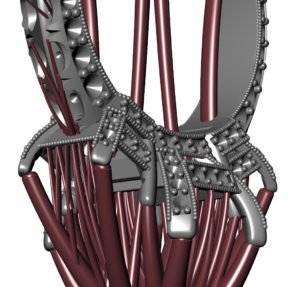

Sometimes that easy button is very attractive, and can be the best choice. The 3-stone ring in the images below has over 95 support elements in it! It took about 1.5 hours to set all these up. This particular job was done on a rush timeline, so Solidscape wasn’t an option. The mill wouldn’t have cut the part properly; there would have been a lot of extra material leftover and detail that isn’t possible on a mill.

Leave a Reply

Want to join the discussion?Feel free to contribute!